Windows are essential in maintaining the temperature of a building and controlling entry of light, air and noise. Due to this, they are also key to managing the energy consumption of a building. Further, a good window can change the environment inside a building for the better. Windows have the potential of transforming a small room to an open hall. Due to their importance, a lot of time is spent by architects and interior designers in deciding the location, size, design and materials for windows in a building.

In this article, we will focus on the evolution of materials used in windows.

Evolution of windows.

Windows have evolved with time. In terms of material, wood has largely given way to Aluminium and uPVC for modern structures. However, wood is still used for buildings demanding a traditional aesthetic.

Wood windows

In the beginning, windows were made completely of wood; the frame as well as shutter. With the advent of glass, wood has lost favour as a shuttering material. Due to mass manufacture, glass is cost effective and is transparent; something no other material can replicate. Modern glass windows originated first in England. Wood-framed windows offer good thermal insulation as well as add a natural elegance to the house. The drawback is that they require periodical maintenance.

Currently, wooden windows cost higher than the aluminum and PVC windows. Availability of good quality wood is limited. Further, the workmanship involved in crafting a good window is high; increasing costs further. A poorly crafted window could expose gaps from which heat and air can enter the building. Since wooden windows are relatively expensive, they are increasingly used in buildings to give a traditional and artistic appearance.

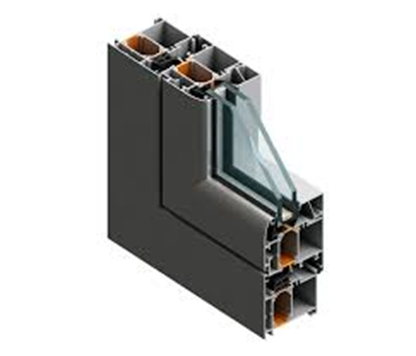

Aluminum framed windows

Aluminum windows were first introduced in the 1940s. American designer Buckminster Fuller was the first to use aluminum frames for glass windows. Mass production of Aluminium profiles paved the way for their extensive use in domestic windows. Aluminum windows have higher strength and therefore the frame width can be much lesser. They are cost-effective, offer a modern aesthetic and do not require high maintenance. Due to standardization of profiles that are used for windows, workmanship required to manufacture a window is relatively lesser compared to wood. One of the disadvantage of Aluminium is that it is a good conductor of heat. Unless thermal barriers are integrated into the design, they will allow heat into the building.

Figure 2 Double glazed aluminum windows

uPVC windows

uPVC or un-plasticized PVC windows are made without plasticizers during the manufacturing process. This makes them much more rigid and strong compared to PVC. However, uPVC windows are further strengthened by reinforcing them with metal. uPVC became popular as a material in windows in the last 20 to 30 years. These windows give a modern look to the house. By using machines to craft a window, higher dimensional tolerances can be achieved; leading to better insulation against noise, rain, pollution and dust. uPVC, being an insulator, also control energy losses. Like Aluminium, the standardization of components make them easy to install. Further, they offer a long life with less maintenance, even higher than Aluminium. In this segment, many organized players compete in the market. Some of the leading manufacturers of uPVC windows are Fenesta, Veka, Kommerling, LG Hausys and Sara Elgi.

Below is a comparison of the three major materials used in windows.

| Materials | Thermal resistance | Durability | Maintenance | Cost | Recycled content |

|---|---|---|---|---|---|

| Wood | Very good | Variable | High | High | Low |

| uPVC | Very good | Very good | Very low | Average | Very low |

| Aluminium | Bad | Good | Very low | low | Typically, > 95% |

Another recent trend is frameless or minimal windows; popular in commercial buildings. Frameless windows do not have visible frames or fixtures. These windows have a hidden structural support and can be as large as 6 meter by 3 meter. They provide a clean and modern look to buildings. They also allow maximum light into the building and are great for providing a panoramic, barrier-free view for residents. Rollwin, Keller AG and Dorma are some of the companies manufacturing frameless windows.

The future of window is likely to revolve around energy conservation and environment protection. While developing alternate materials, the entire energy and environment lifecycle would be considered; manufacturing, transportation, in-use and disposal. We hope that improved versions of existing materials or alternate new materials will be developed such that the lifecycle energy and environment costs are lower.